Description

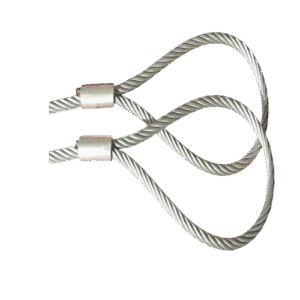

Steel Wire Rope is a high-strength, flexible mechanical cable composed of multiple strands of steel wires twisted together around a central core. It is designed to withstand tensile forces, abrasion, fatigue, and corrosion, making it ideal for lifting, hoisting, towing, rigging, anchoring, and structural support applications. Wire ropes are manufactured in various constructions, such as 6×19, 6×37, 7×19, or 8×19, referring to the number of strands and wires per strand. They may also include different core types like fiber core (FC) for flexibility or independent wire rope core (IWRC) for added strength and resistance to crushing. Wire ropes can be galvanized, stainless steel, or uncoated bright steel, depending on corrosion resistance requirements.

Rope Construction

6×25Fi+FC, 6x26WS+FC, 6×29Fi+FC, 6x31WS+FC, 6x36WS+FC, 6×37+FC, 6x41WS+FC, 6x49SWS+FC, 6x55SWS+FC, 6×25Fi+IWR, 6×26WS+IWR, 6×29Fi+IWR, 6×31WS+IWR, 6×36WS+IWR, 6×37+IWR, 6×41WS+IWR, 6×49SWS+IWR,

6×55SWS+IWR.

6×25Fi: It is used in blast furnace hoisting, petroleum drilling, heavy-duty crane (steel core), heavy lifting and other important usage of crane, steel heat transfer machine (steel core), Shipping handling.

6×26WS: It is used in blast furnace hoisting, petroleum drilling, heavy lifting and other important usage of crane.

6×29Fi: It is used in blast furnace hoisting. petroleum driling, heavy lifting and other important uses of crane, steel heat transfer machine (steel core), shipping handling.

6×31WS: It is used in blast furnace hoisting, petroleum drilling, heavy lifting and other important uses of crane, steel heat transfer machine (steel core), shipping handling, tow boat, cargo net.

6x36WS: It is used in balance shaft rope (only interactive twist), blast furnace hoisting, petroleum drilling, heavy lifting and other important uses of crane, steel heat transfer machine (steel core), shipping handling, tow boat, cargo net, salvage.

6×37S: It is used in balance shaft rope (only interactive twist), heavy lifting and other important uses of crane, steel heat transfer machine (steel core), shipping handling, tow boat, cargo net, salvage.

6×49SWS, 6×55SWS: It is used in heavy lifting and other important usage of crane, salvage.

Feature of Steel Wire Rope

- Advanced Manufacturing Equipment: Equipped with large, medium and small wire rope manufacturing workshops with advanced technology, sophisticated equipment and complete product varieties.

- Production Capacity: Annual production capacity over 100,000 ton. One of the professional manufacturing bases of wire rope with the largest production volume and specifications in China

- Well-experienced: Nearly 40 years of OEM&ODM manufacturing and export experience, Professional technical team, Support customized product

- Standards: Perform national and international standards, GB/T20118, EN , Gost, API.

- High quality: Strict quality control before ,in and after production, Authoritative testing report can be provided

- Place of Origin: Hebei, China

Technical Specification of Steel Wire Rope

- Diameter from 6mm to 260mm with various point and line contacts wire rope, compacted strand wire rope

- Rope tensile strength grade from 1570Mpa to 2160Mpa

- Production standard can be the national and international standards

- Length: Customized

- Surface: Galvanized/ Smooth

Round Strand Wire Rope

Rope Type Typical Construction Rope Diameter(mm) Rope Type Typical Construction Rope Diameter(mm) Wire Rope Strand Wire Rope Strand Single-strand

wire rope1×7 (1+6) 6~16 6×24 6×24S (FC+12+12) 14~44 1×19 (1+6+12) 10~30 6×24W (FC+8+8/8) 14~44 1×37 (1+6+12+18) 14~42 8×19 8×19S (1+9+9) 16~50 1×61 (1+6+12+18+24) 20~54 8×19W (1+6+6/6) 16~50 1×91 (1+6+12+18+24+30) 30~66 8×25Fi (1+6+6F+12) 18~56 1×127~1×631 — 50~160 8×26WS (1+5+5/5+10) 16~54 6×7 6×7 (1+6) 6~36 8×31WS (1+6+6/6+12) 16~60 6×19(a) 6×19S (1+9+9) 12~42 8×37(a) 8×36WS (1+7+7/7+14) 18~108 6×19W (1+6+6/6) 12~42 8×41WS (1+8+8/8+16) 28~120 6×25Fi (1+6+6F+12) 16~42 8×49SWS (1+8+8+8/8+16) 40~120 6×26WS (1+5+5/5+10) 16~42 8×55SWS (1+9+9+9/9+18) 40~124 6×31WS (1+6+6/6+12) 18~42 8×37(b) 8×37 (1+6+12+18) 60~86 6×19(b) 6×19 (1+6+12) 9~46 8×61(a) 8×61FWS (1+5+5F+10+10/10+20) 60~136 6×37(a) 6×29Fi (1+7+7F+14) 18~64 8×64SFS (1+9+9+9F+18+18) 60~124 6×36WS (1+7+7/7+14) 16~90 8×61(ab) 8×65FNS (1+6+6F+12-20+20) 60~140 6×41WS (1+8+8/8+16) 38~100 8×80WSNS (1+7+7/7+14-22+22) 50~158 6×49SWS (1+8+8+8/8+16) 38~100 8×84WSNS (1+7+7/7+14-24+24) 60~172 6×55SWS (1+9+9+9/9+18) 38~100 8×91(ab) 8×111SWSNS (1+9+9+9/9+18-28+28 60~156 6×37WS (1+6+15+15) 16~64 8×103FSNS (1+7+7F+14+14-30+30) 60~190 6×37(b) 6×37 (1+6+12+18) 13~66 8×109SWSNS (1+8+8+8/8+16-30+30) 60~190 6×61(a) 6×61FWS (1+5+5F+10+10/10+20) 60~110 8×61(b) 8×61 (1+6+12+18+24) 60~134 6×64FS (1+9+9+9F+18+18) 60~100 18×7 17×7 (1+6) 12~44 6×61(ab) 6×65FNS (1+6+6F+12-20+20) 60~116 18×7 (1+6) 12~55 6×80WSNS (1+7+7/7+14-22+22) 60~130 18×19 18×19S (1+9+9) 18~50 6×84WSNS (1+7+7/7+14-24+24) 60~142 18×19W (1+6+6/6) 14~50 6×91(ab) 6×111SWSNS (1+9+9+9/9+18-28+28) 60~128 18×19 (1+6+12) 14~50 6×103FSNS (1+7+7F+14+14-30+30) 60~156 34×7 34×7 (1+6) 16~60 6×109SWSNS (1+8+8+8/8+16-30+30) 60~156 36×7 (1+6) 16~60 6×61(b) 6×61 (1+6+12+18+24) 40~110 35W×7 35W×7 (1+6) 16~60 6×12 6×12 (FC+12) 8~32 24W×7 (1+6) 16~50 6×24 6×24 (FC+9+15) 30~46 Shaped Strand Wire Rope

Rope Type Typical Construction Rope Diameter(mm) Rope Type Typical Construction Rope Diameter(mm) Wire Rope Strand Wire Rope Strand 4V×39 4V×39S (FC+9+15+15) 14~46 6V×19 6V×30 (6+12+12) 22~38 4V×48S (FC+12+18+18) 20~50 6V×34 (/1×7+3/+12+12) 28~44 6V×7 6V×19 (/1×7+3/+9) 20~36 6V×37 6V×37 (/1×7+3/+12+15) 32~52 6V×19 6V×21 (FC+9+12) 18~36 6V×37S (/1×7+3/+12+15) 32~52 6V×24 (FC+12+12) 18~36 6V×43 (/1×7+3/+15+18) 38~58 Compacted Strand Wire Rope

Rope Type Typical Construction Rope Diameter(mm) Rope Type Typical Construction Rope Diameter(mm) Wire Rope Strand Wire Rope Strand 6×K7 6×K7 1+6 10~40 8×K36-PWRC(K) 8×K36WS-PWRC(K) 1+7+7/7+14 22~60 6×K19 6×K19S 1+9+9 12~40 15×K7 15×K7 1+6 22~60 6×K26WS 1+5+5/5+10 14~40 16×K7 16×K7 1+6 22~60 6×K31WS 1+6+6/6+12 16~40 18×K7 18×K7 1+6 14~48 6×K36 6×K36WS 1+7+7/7+14 24~68 18×K9 18×K9S 1+9+9 24~60 6×K41WS 1+8+8/8+16 38~68 35W×K7 35W×K7 1+6 14~42 8×K19 8×K17S 1+8+8 16~38 35W×K19S 1+9+9 35~52 8×K19S 1+9+9 16~40 35W×K26WS 1+5+5/5+10 40~60 8×K26WS 1+5+5/5+10 20~42 JL·1618K JL·1618K 1+6 18~60 8×K31WS 1+6+6/6+12 24~50 JL·1710K JL·1710K26WS 1+5+5/5+10 20~50 8×K36 8×K36WS 1+7+7/7+14 28~78 JL·1710K31WS 1+6+6/6+12 20~50 8×K41WS 1+8+8/8+16 30~78 JL·1710K36WS 1+7+7/7+14 30~50 8×K19-PWRC(K) 8×K19S-PWRC(K) 1+9+9 20~48 JL·1712K JL·1712K7 1+6 20~40 8×K26WS-PWRC(K) 1+5+5/5+10 20~48 JL·1710K719S 1+9+9 30~60 8×K31WS-PWRC(K) 1+6+6/6+12 20~56 Steel Cable

Rope Type Typical Construction Rope Diameter(mm) Rope Type Typical Construction Rope Diameter(mm) Wire Rope Strand Wire Rope Strand 7×[6×37(a)+IWR] 6×[6×36WS+IWR]+IWRC 192~260 9×[6×37(a)+IWR] 8×[6×36WS+IWR]+IWRC 192~260 6×[6×41WS+IWR]+IWRC 192~260 8×[6×41WS+IWR]+IWRC 192~260 6×[6×49SWS+IWR]+IWRC 192~260 8×[6×49SWS+IWR]+IWRC 192~260 7×[6×61(a)+IWR] 6×[6×55SWS+IWR]+IWRC 192~260 9×[6×61(a)+IWR] 8×[6×55SWS+IWR]+IWRC 192~260 6×[6×61FWS+IWR]+IWRC 192~260 8×[6×61FWS+IWR]+IWRC 192~260 6×[6×64SFS+IWR]+IWRC 192~260 6×[6×64SFS+IWR]+IWRC 192~260 7×[6×37(b)+IWR] 6×[6×37+IWR]+IWRC 192~260 9×[6×37(b)+IWR] 8×[6×37+IWR]+IWRC 192~260 7×[6×61(b)+IWR] 6×[6×61+IWR]+IWRC 192~260 9×[6×61(b)+IWR] 8×[6×61+IWR]+IWRC 192~260

Reviews

There are no reviews yet.